Inventory management can look a little different depending on the size and industry of your business. To better highlight these contrasts, let’s explore some of the more common inventory management examples you’re likely to encounter. Dealing with different order quantities, replenishment cycle times, safety stock, forecasts, and seasonality can be complicated. Stock takes, also known as stock counts, help you understand how much of each item you have available. You can use stocktaking software to streamline this process, but it’s important to perform semi-regular manual counts to spot any discrepancies contribution margin caused by shrinkage or spoilage.

Monitor and Adapt Your Inventory Management Strategies

This technique can reduce handling and holding costs while improving fulfillment times, and is most commonly used for perishable products. However, it requires a lot of coordination with your suppliers and isn’t a good fit for companies selling non-perishable products or products with low turnover. One of the first steps to simplifying inventory management is integrating modern software solutions.

Materials Requirement Planning (MRP)

It provides a tamper-proof record of transactions, improving traceability and reducing fraud. Regularly update your warehouse layout based on sales trends and seasonality. Dynamic slotting keeps your warehouse organized and responsive to changing demand patterns.

Just-in-time inventory

Comprehensive inventory management systems integrate customer order processing, real-time inventory monitoring, and supplier information in a single interface. This greatly enhances productivity by streamlining what would otherwise be a complex task when using separate platforms. Having good inventory management operations can improve customer experience. Having the wrong quantity on hand or missing products can lead to customer dissatisfaction.

- This automatic process helps ensure that stock is replenished before it runs out, preventing stockouts and ensuring smooth operations.

- This technique eliminates or minimizes storage time, enabling faster product movement from suppliers to customers.

- Minimum order quantity (MOQ) is the smallest amount of set stock a given supplier is willing to sell.

- To ensure timely replenishment, regularly review and adjust reorder points based on current data.

Retailers get minimal risk, improved cash flow, and lower cost of ownership. The DMAIC process uses data and measured objectives to create a cycle of continuous improvement in manufacturing methods. DMAIC is useful to improve your current processes, but Six Sigma also uses DMADV to develop new processes, products, or services. Let’s take a look at 12 of the most widely used inventory techniques today. These are highly effective techniques you can use to improve inventory control in your business.

- It is based on the principle that the first inventory items purchased or produced are the first to be sold or used.

- This data shows the vital role of inventory management systems in maintaining operational success.

- Using the oldest inventory first helps ensure that items are sold or used before they become outdated or lose value.

- However, combining it with a perpetual system provides real-time data, enhancing decision-making and responsiveness to demand fluctuations.

- These systems analyze data to identify potential problems and areas for improvement, facilitating more strategic decision-making.

A Stock Keeping Unit, or SKU, is a unique identifier assigned to each product in your inventory. SKUs are essential for tracking stock levels, managing reorders, and organizing your products efficiently. For Bookstime example, a black t-shirt in size small will have a different SKU than the same t-shirt in size large. By using SKUs, businesses can quickly locate items, track sales trends, and reduce the risk of errors in inventory counts. Spreadsheets, hand-counted stock levels and manual order placement have largely been replaced by advanced inventory tracking software. An inventory management system can simplify the process of ordering, storing and using inventory by automating end-to-end production, business management, demand forecasting and accounting.

- Imagine losing sales because popular items are out of stock or having your cash tied up in unsold products that take up valuable space.

- Keep in mind that you can combine ERP inventory management with various inventory management techniques.

- Inventory management eliminates the inefficiencies that lead to lost stock, overstocking, and stockouts – reducing inventory carrying costs and improving profit margins.

- Inventory management, a critical element of the supply chain, is tracking inventory from manufacturers to warehouses and from these facilities to the point of sale.

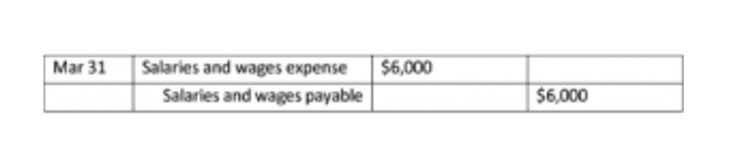

- First in, first out (FIFO) and last in, first out (LIFO) are two inventory management methods that govern which inventory is sold first.

- That’s why LIFO is not allowed under some accounting standards, like IFRS.

How EOQ Optimizes Inventory Levels

Although online store inventory management typically calculated using pen and paper or Excel spreadsheets, a perpetual inventory system records inventory changes in real time using computerized point-of-sale systems. In contrast to enterprise resource planning (ERP) software, inventory management software focuses on a single supply chain process. It can integrate with other system solutions, including point of sale (POS) software, shipping, and sales channel management. This helps companies build a personalized integration stack that can meet their daily needs.